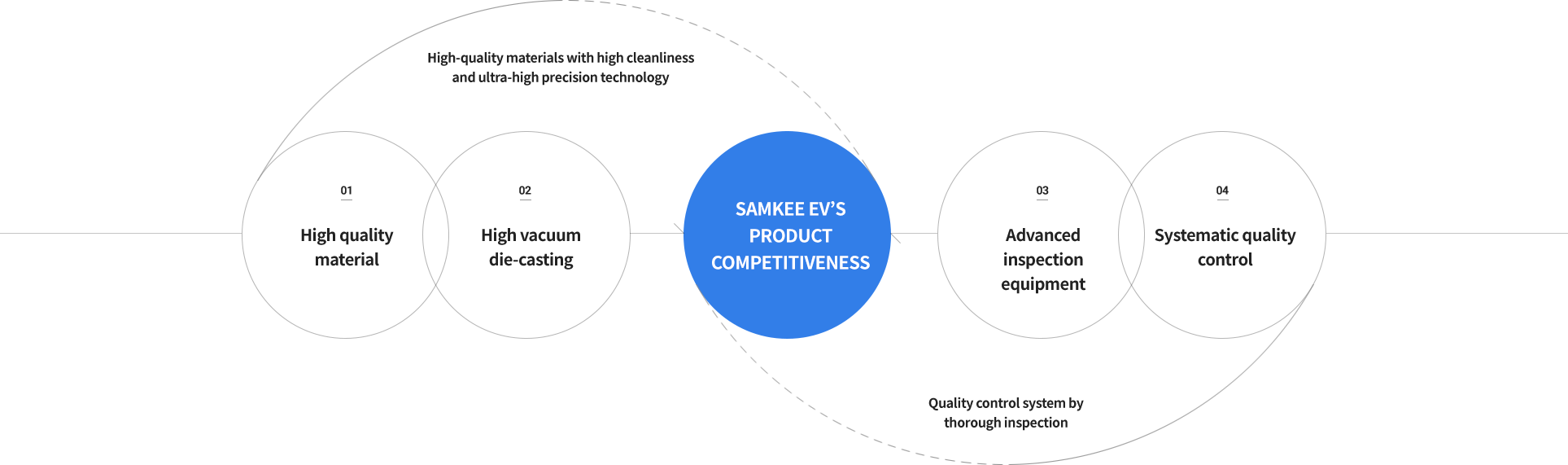

Products

Product

Competitiveness

We use high-quality materials with high cleanliness

to match the mechanical properties of each product

SAMKEE ENERGY SOLUTIONS has its own alloy technology, so materials with excellent mechanical properties are

applied to meet the requirements of each product

High quality material

We minimize impurities by using high-quality materials and apply

excellent materials by using our own alloy technology

We minimize impurities by GBF treatment for the quality of aluminum molten metal with high cleanliness,

In addition, since we have our own alloy technology, we apply materials with excellent mechanical properties

to meet the requirements of each product

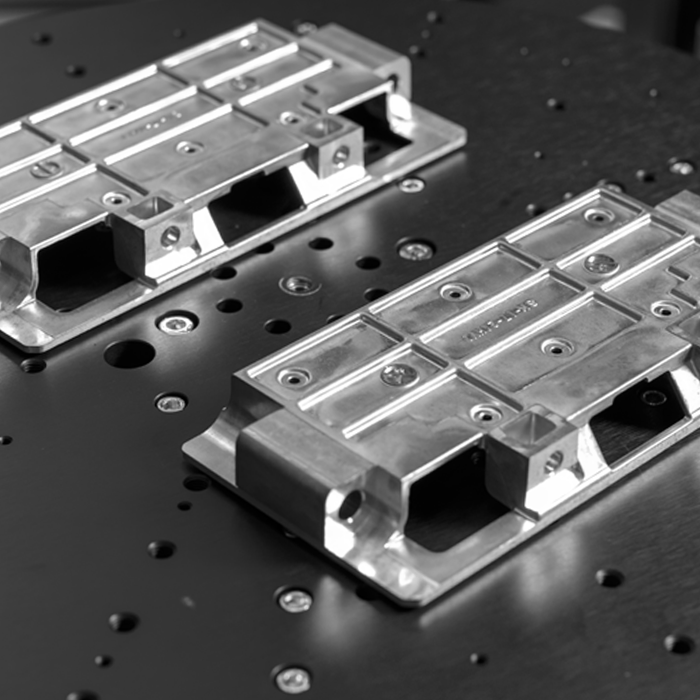

High vacuum die-casting

SAMKEE ENERGY SOLUTIONS's own die-casting method using

die-casting know-how and mold sealing technology

In products that require safety and precision, such as EV battery components, internal defects that are not detected with visual inspection are a top priority to reduce

We are minimizing pores and defects inside the product with our high-vacuum die-casting method that applies die-casting know-how and mold sealing technology in various automotive parts fields

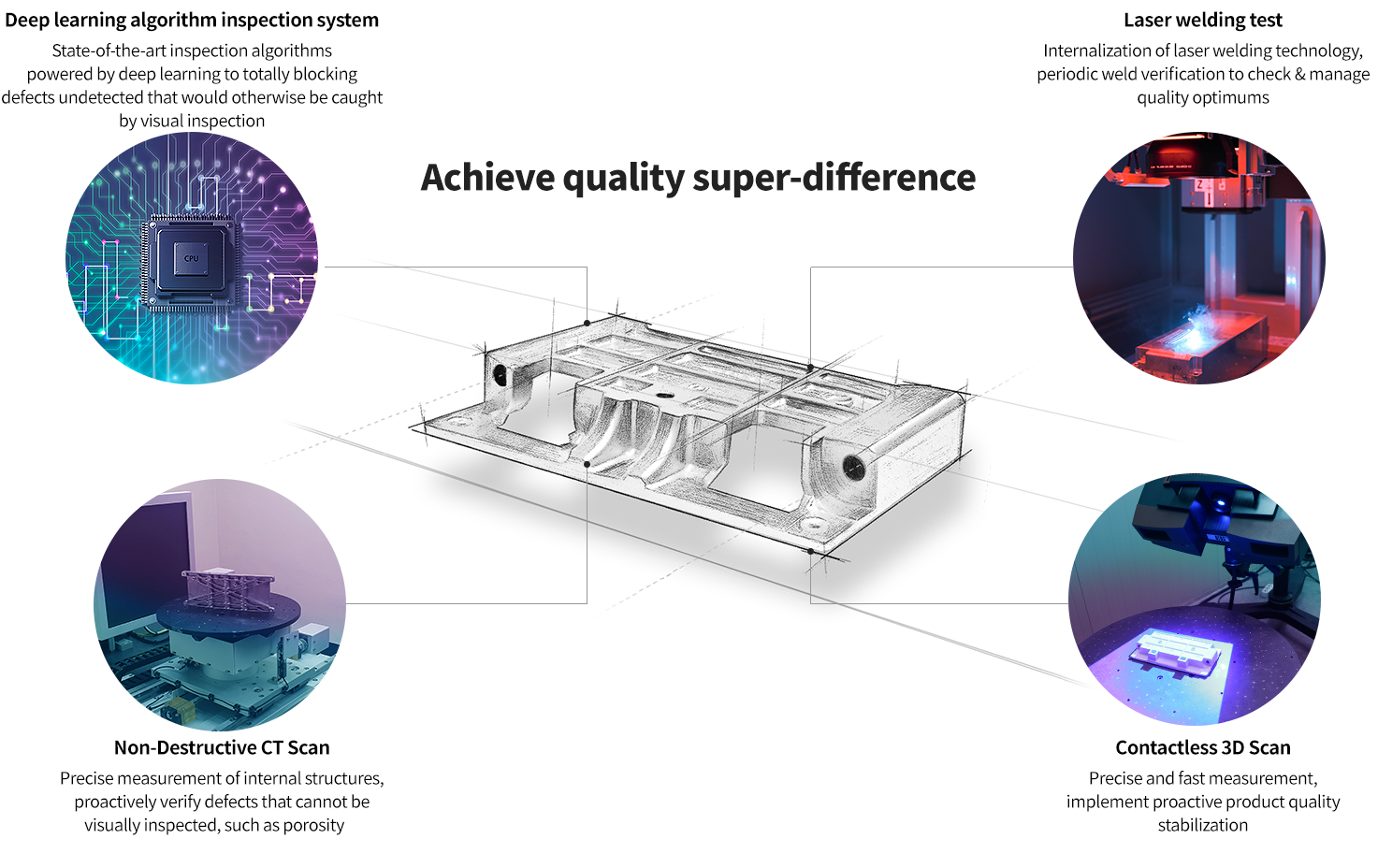

Advanced inspection equipment

SAMKEE ENERGY SOLUTIONS's own deep learning algorithm is applied to increase the reliability of the inspection

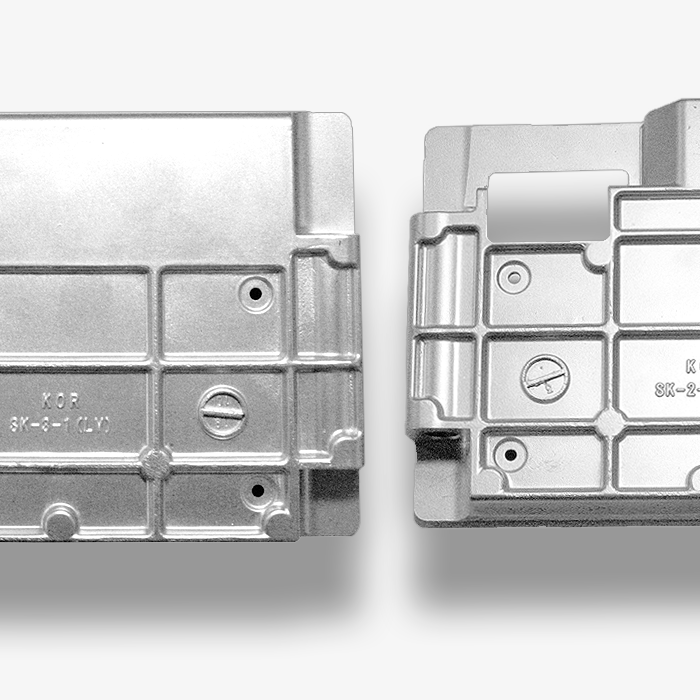

End plate products are produced through aluminum high-pressure casting

Due to the nature of high-pressure casting products, there are various types of defects such as bubble,

dents, mill scale, blisters, etc. exist, and high-accuracy detection is very difficult

SAMKEE ENERGY SOLUTIONS applies a state-of-the-art inspection algorithm using

deep learning to increase the reliability of inspection and fundamentally blocks the leakage of defects that may occur during visual inspection